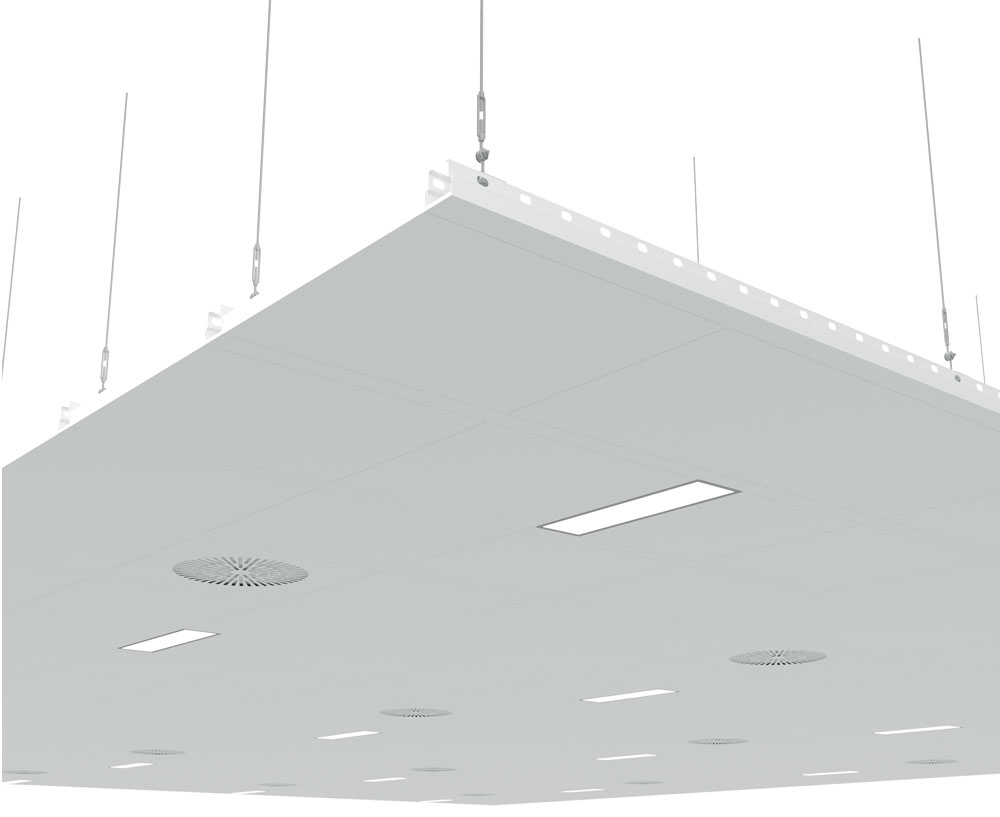

Wiring is done within the band grid. Individual functional elements can be added or replaced at any time. The ceil-tek is not accessible as standard. Optionally, it can be made fully or partially accessible. Complies with the high requirements of the EC GMP guidelines and DIN EN ISO 14644.

Cleanroom ceilings - from our own production

As a system supplier, we have several cleanroom ceiling systems developed in-house, all of which are characterised by their flexibility and maximum modularity. Thanks to our own production and all components that have been tried and tested over many years, we can offer an optimal cleanroom solution for almost any requirement.

clean-tek offers bandraster, T-grid and a clamping cassette ceiling. These can be fully, partially or non-accessible. In accordance with EC-GMP guidelines and DIN EN ISO, all cleanroom classes can be realised. Our experienced technicians and engineers always design your cleanroom ceiling, including all installation components, to fit your individual application.

Our cleanroom ceiling systems:

More information

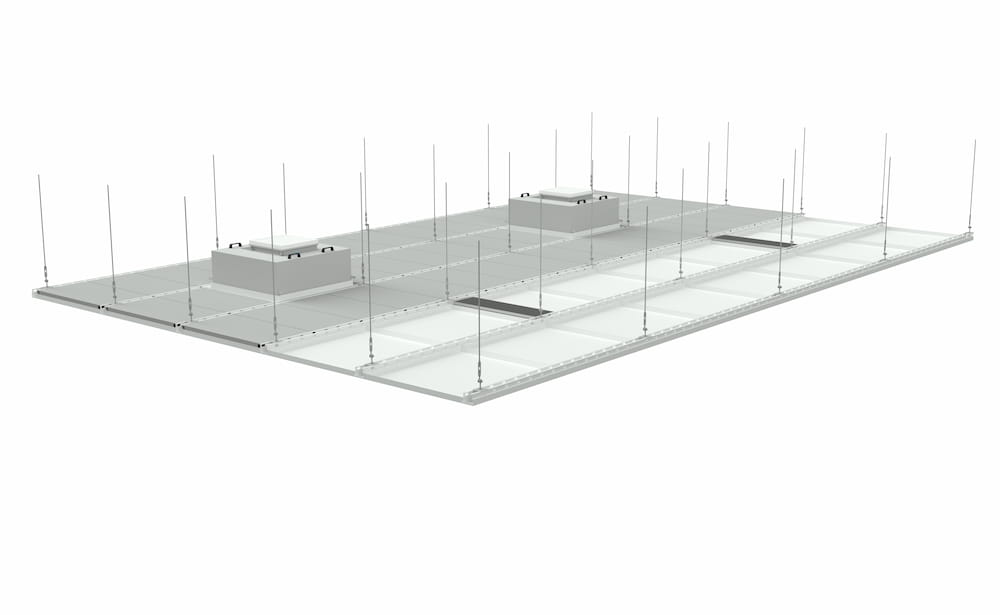

The ceil-tek ribbon grid ceiling is a cleanroom ceiling that is flush with the surface on both sides and can optionally be walked on. It complies with the high requirements of the EC GMP guidelines as well as DIN EN ISO 14644. In many cases, it has been able to firmly establish itself in the pharmaceutical and biotechnology industries as a tried and tested system. The system consists of a parallel ceiling girder system (band grid) and the ceiling panels in between. The bandraster is suspended on height-adjustable threaded rods from the on-site ceiling or a steel structure. All built-in components such as luminaires, filter fan units and ceiling panels are inserted between the supports. Cabling is possible within the band grid. Individual cassettes and functional elements can be added or replaced at any time. As standard, the ceil-tek cannot be walked on. Optionally, it can be made fully or partially accessible.

Features and Benefits:

- Optionally fully, partially or not walkable

- Complies with FDA, GMP, DIN EN ISO and WHO requirements

- All elements can be replaced independently of adjacent panels

- Avoidance of tripping accidents due to media guidance in the band grid

- Compatible with all common installation parts

- Safe planning and fast installation thanks to standardised grid dimensions

- Suitable for all cleanroom classes

- Any cleanroom area can be realised

- Future-proof investment thanks to a 10-year subsequent delivery guarantee for all conversion and supplementary components

- Easy to clean and resistant to disinfectants

Installation parts and Options:

- Fan Filter Unit / Filter Boxes / Recirculation Modules

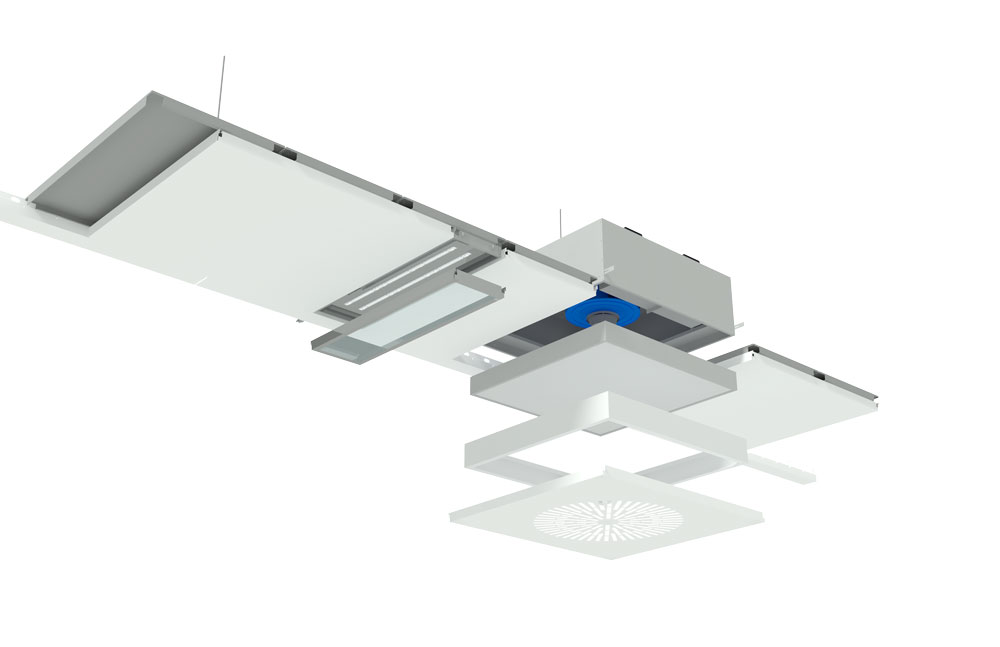

Matching the ceiling system, clean-tek offers factory-made FFUs which can be integrated exactly into the ceiling grid. For the integration of third-party products, an interface clarification by means of a detailed drawing is required. Filter boxes, which are connected to the on-site ventilation system, as well as special recirculation air modules can also be integrated into the ceil-tek ribbon grid ceiling according to individual detailed planning. - Air Diffusers

Ceiling diffusers are used to ventilate the clean room. To guarantee flush installation of each brand, clean-tek also supplies the appropriate adapter frame if required. clean-tek supplies swirl diffusers, CG distributors (laminators) or perforated plates depending on the on-site requirements. - LED Cleanroom Lights

To match the cleanroom ceiling system, clean-tek offers the factory's own bandraster LED lighting, BRL for short. Similar to a ceiling plate, the BRL has a suspension system so that the luminaire is suspended between two ceiling beams. A cut-out in the ceiling panel is not required for this. Alternatively, a factory-made square LED recessed luminaire, EBL for short, can also be integrated. However, this requires a cut-out in the ceiling system as well as an additional set-up kit for flush integration of the luminaire into the ceiling cut-out. For the integration of external lighting, the interface must be clarified by means of a detailed drawing. - Cable and media routing

The clean and complete cable and media routing within the belt grid ensures a high level of working safety for cleanroom ceilings that can be walked on. - Cable routing of return air ducts

After individual planning of the interface between the ceiling system and the ventilation duct, clean-tek also offers return air ducts for integrating the exhaust air to the ventilation system. - Sound insulation

On request, special sound insulation panels can be installed in the false ceiling. The leakage of particles is reliably prevented by the firm sheathing with a suitable plastic foil. - Fall protection

To avoid hazards with accessible suspended ceilings, it is often advisable to install fall protection. With regard to the design, individual detailed planning is always required. - Installation of fire alarm systems

Sprinklers and fire detectors can be integrated at any point in the ceiling plate. Integration into the ceiling support system is only permissible with the non-accessible ceiling system, as otherwise accessibility is impaired. With regard to the design, individual detailed planning is always required.

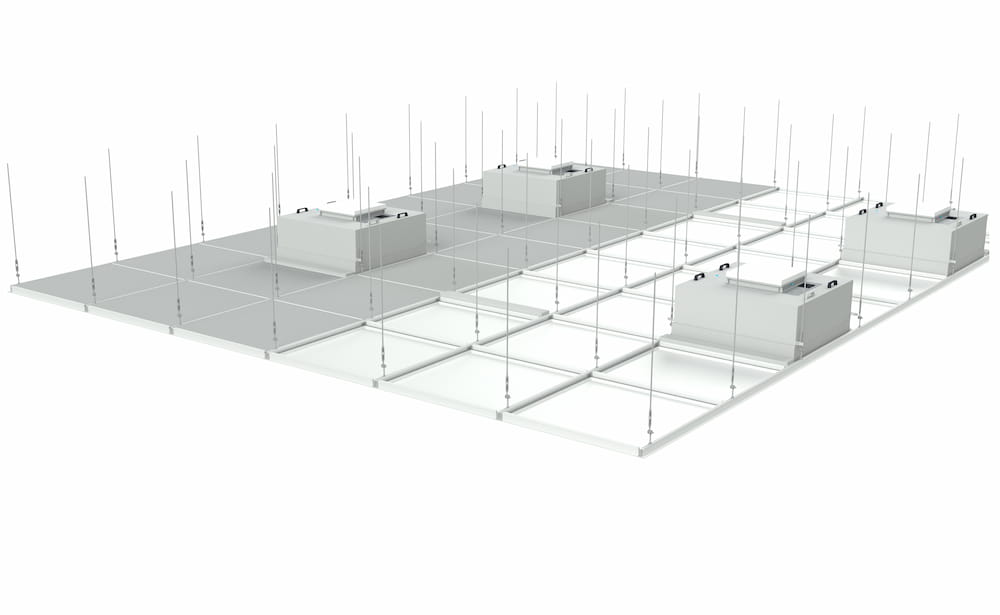

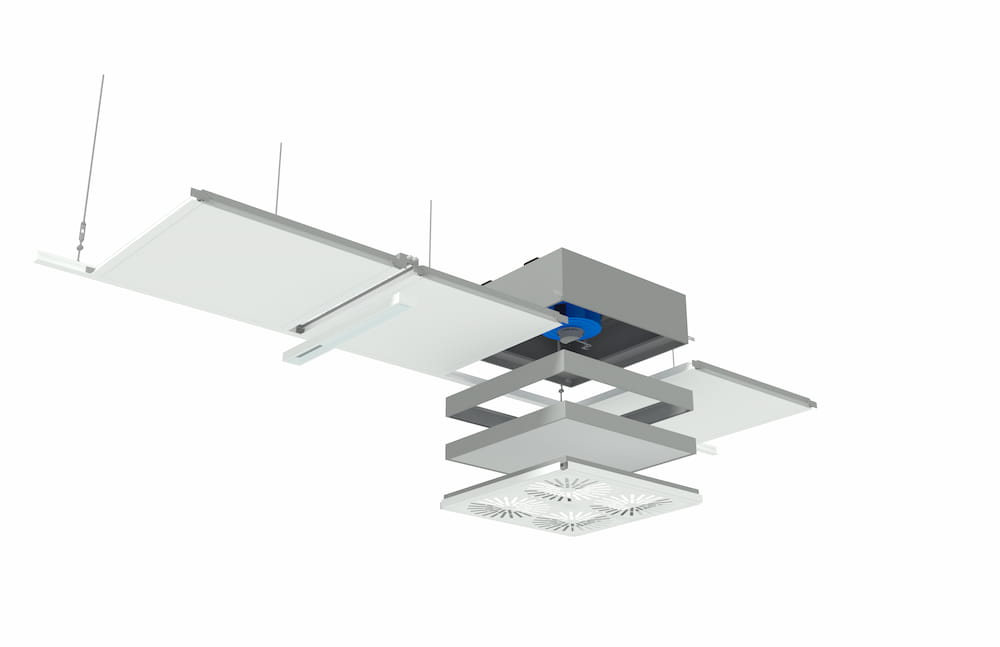

The T-Grid cross-ribbon grid ceiling is a highly flexible ceiling system that can also be designed as a partial or fully accessible ceiling with appropriate suspension. The system meets the high requirements of the EC GMP guidelines and DIN EN ISO 14644.

The ceiling system is suspended from the support profiles or from the transoms. This offers maximum flexibility with regard to the positioning of the suspension. The ceiling grid can be produced in any grid dimension. Standard dimensions are recommended, however, as some third-party installation parts are based on these standard dimensions.

The ceiling panels are inserted into the ceiling grid from above. Flush installation is possible on request. All built-in parts such as luminaires, filter fan units and ceiling panels are installed between the beams, filter fan units and ceiling panels.

The T-Grid cross-ribbon grid ceiling is a highly flexible ceiling system that can also be designed as a partial or fully accessible ceiling with appropriate suspension. The system meets the high requirements of the EC GMP guidelines and DIN EN ISO 14644.

The ceiling system is suspended from the support profiles or from the transoms. This offers maximum flexibility with regard to the positioning of the suspension. The ceiling grid can be produced in any grid dimension. Standard dimensions are recommended, however, as some third-party installation parts are based on these standard dimensions.

The ceiling panels are inserted into the ceiling grid from above. Flush installation is possible on request. All built-in parts such as luminaires, filter fan units and ceiling panels are installed between the beams, filter fan units and ceiling panels.

Features and Benefits

- Optionally fully, partially or not walkable

- Complies with FDA, GMP, DIN EN ISO and WHO requirements

- All elements can be replaced independently of adjacent panels

- Maintenance of common built-in parts possible from above or from the cleanroom side

- Compatible with all common installation parts

- Highly flexible. All grid dimensions are possible

- Suitable for all cleanroom classes

- Any cleanroom area can be realised

- Future-proof investment thanks to a 10-year subsequent delivery guarantee for all conversion and supplementary components

- Easy to clean and resistant to disinfectants

Installation parts and Options

- Fan Filter Unit / Filter Boxes / Recirculation Modules

clean-tek offers factory-made FFUs to match the ceiling system, which can be integrated exactly into the ceiling grid. For the integration of third-party products, an interface clarification by means of a detailed drawing is required. Filter boxes, which are connected to the on-site ventilation system, as well as special recirculation modules can also be integrated into the T-Grid cross-ribbon grid ceiling after individual detailed planning. - Air diffusers

Ceiling diffusers are used for the ventilation of the clean room. To guarantee flush installation of each brand, clean-tek also supplies the corresponding adapter frame if required. clean-tek supplies swirl diffusers, CG distributors (laminators) or perforated plates depending on the customer's requirements. - LED clean-tek luminaires

To match the ceiling system, clean-tek offers the factory-made rectangular LED recessed luminaire, TGL for short. The TGL is inserted into the ceiling grid in a similar way to a ceiling plate. A cut-out in the ceiling panel is not necessary. Alternatively, a factory-made square LED recessed luminaire, EBL for short, can also be integrated. However, this requires a cut-out in the ceiling system as well as an additional set-up set for the flush integration of the luminaire into the ceiling cut-out. For the integration of external lighting, the interface must be clarified by means of a detailed drawing. - Channel routing of return air shafts

After individual planning of the interface between the ceiling system and the ventilation duct, clean-tek also offers return air ducts for the integration of the exhaust air to the ventilation system. - Sound insulation

On request, special sound insulation panels can be installed in the false ceiling. The leakage of particles is reliably prevented by the firm sheathing with a suitable plastic foil. - Fall protection

To avoid hazards with accessible suspended ceilings, it is often advisable to install fall protection. With regard to the design, individual detailed planning is always required. - Installation of fire alarm systems

Sprinklers and fire detectors can be integrated at any point in the ceiling plate. Integration into the ceiling support system is only permissible with the non-accessible ceiling system, as otherwise accessibility is impaired. With regard to the design, individual detailed planning is always required.

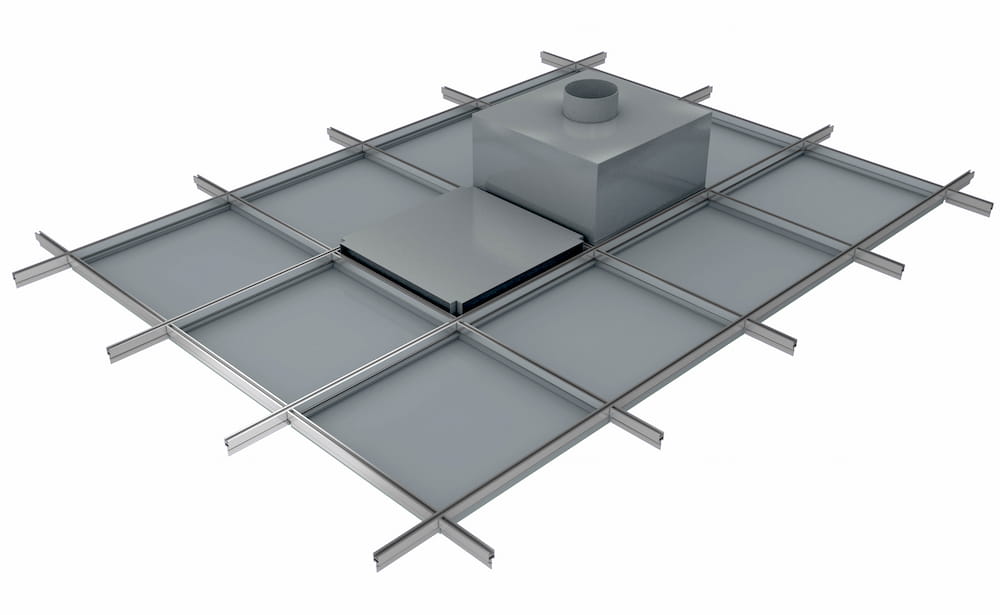

The ceiling system is a rational and perfect solution for single-shell, non-accessible and absolutely flush grid ceilings. The standardised grid dimensions (625 x 1250 or 625 x 625 mm) guarantee customised solutions in every case. The room layout and the structure of the partition walls can be made independently of the grid ceiling.

- Single-shell flush cleanroom ceiling

- Suitable for pressure ranges from -50 Pa to +50 Pa

- Grid dimensions 625x625mm, 625x1250 mm or 600x600mm, 600 x 1200 mm

- Standard colour RAL 9010 or 9002

- Installation kits for ceiling diffuser, return air diffuser and lighting

- The ceiling is quick and easy to install

- Can be converted and added to at any time

If you have any questions about the design or technology, please contact us.