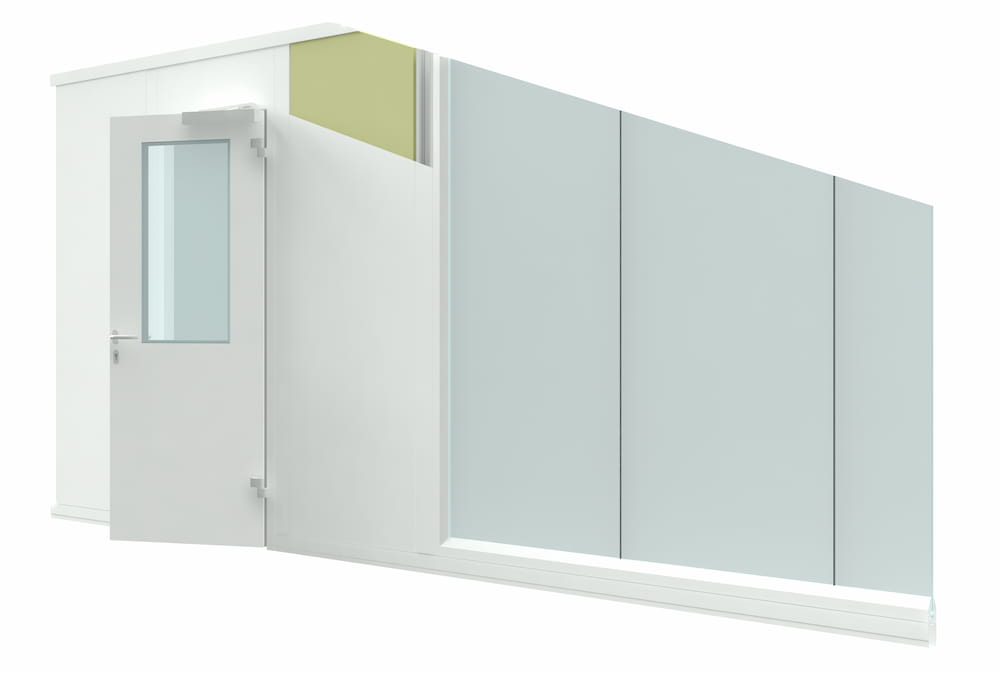

Cleanroom wall in sandwich construction. Available with a width of 50 mm or 100 mm. Proven wall system in GMP areas.

Cleanroom walls - from our own production

We have several cleanroom wall systems at our disposal, all of which are characterised by their compatibility with each other and a high degree of flexibility. We do not simply manufacture wall panels, but as a system supplier we offer you a modular system with which we develop optimal cleanroom solutions. Depending on the requirements, clean-tek offers monoblock elements or elements in shell construction made of coated sheet steel, aluminium or stainless steel and also a full glass wall. All our cleanroom walls are GMP-compliant and flush. Individual wall elements can be replaced at any time if the room layout changes or new machines are added. Our wall systems also offer maximum flexibility in terms of media supply.

Overview of our cleanroom walls

More information

The GMP 50 / GMP 100 cleanroom wall is a sandwich construction and is provided with a filling which is selected according to the application. The individual wall panels can always be manufactured to fit exactly for each application and can also be replaced individually at any time later. The choice of material depends on your production. We offer the GMP wall in galvanised sheet steel, stainless steel (V2A and V4A) or aluminium.

Features and advantages:

- Maximum flexibility through a simple but very stable system

- Can be combined with all clean-tek systems, for example glass walls, spandrel glazing elements as well as with all doors, gates and sluices

- Perfectly coordinated system combination

- Wall cut-outs possible

- Individual wall elements can be converted and removed without dismantling neighbouring elements

- Concealed installation of media and supply connections

- Media ducts are easily accessible

- Compensation for uneven floors possible

- High degree of prefabrication ensures rapid implementation even for extensive construction projects

- The GMP wall is fully recyclable: top layer and filling can be separated from each other and disposed of

- No carrier material for microbiological growth

- The GMP wall can be designed as a strip or axial grid wall

The Bi-Wall cleanroom wall is manufactured in shell construction and complies with the high requirements of the EC GMP guidelines and DIN EN ISO 14644. Preferably used as a partition wall with high flush-mounted installation density. Instead of a wall infill, there is a cavity between the two wall shells, which allows the concealed installation of cable and media lines. The individual wall panels can always be manufactured to fit each application exactly and can also be replaced individually at any time later. The choice of material depends decisively on your production. We offer the wall system in galvanised sheet steel, stainless steel (V2A) or aluminium.

Features and advantages:

- Concealed installation of media and supply connections

- Cables and lines can be routed into adjacent wall elements

- Can be combined with all clean-tek systems with all glass walls, spandrel glazing elements as well as all doors, gates and airlocks

- Perfectly coordinated system combination

- Wall cut-outs are possible

- Individual wall elements can be converted and removed without dismantling neighbouring elements

- Compensation for uneven floors possible

- High degree of prefabrication ensures rapid implementation, even for extensive building projects

- The Bi-Wall is completely recyclable

- No carrier material for microbiological growth

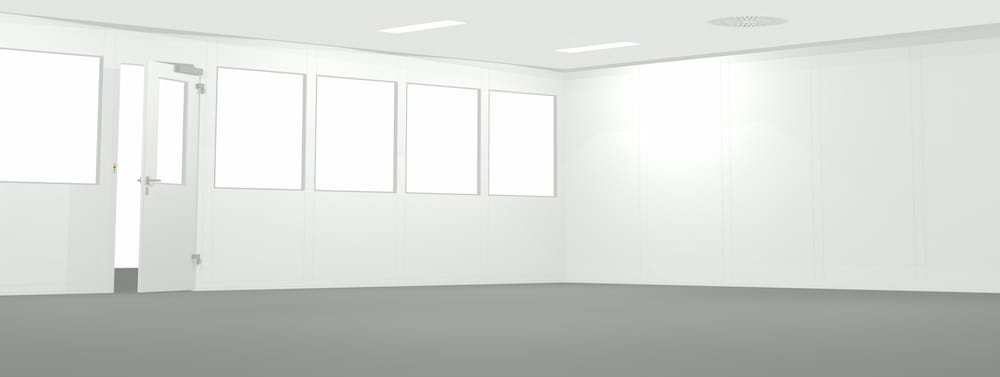

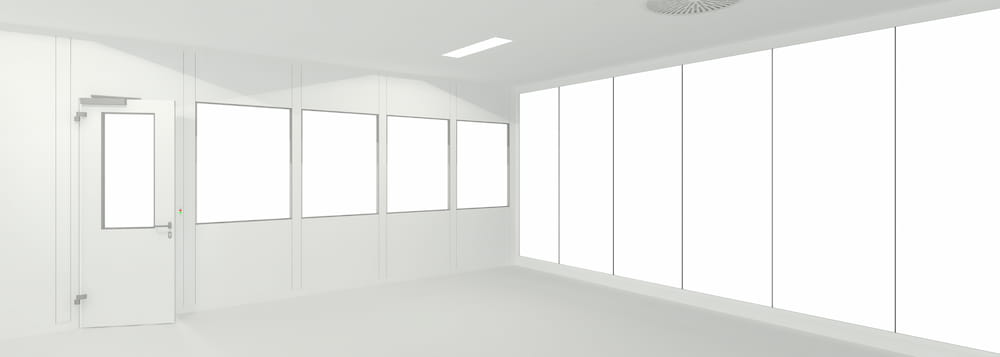

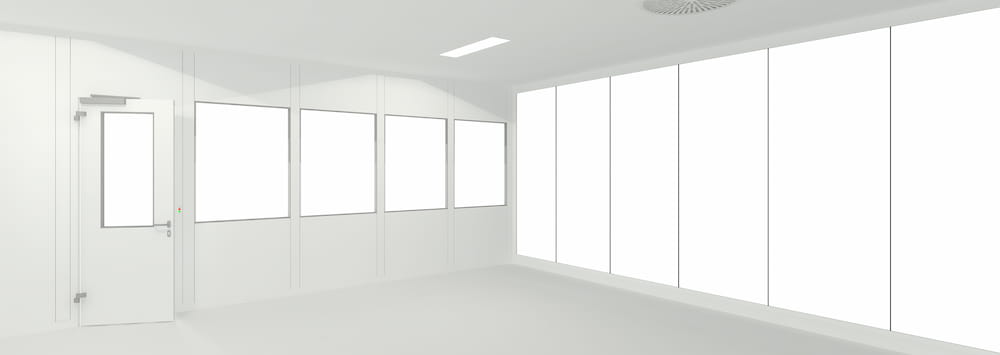

Glass walls create transparency. They provide a view into production and create a special working atmosphere. They avoid the isolation of employees in small, closed rooms and increase safety and order, as workplaces can be better overlooked. The all-glass wall from clean-tek meets the high requirements of the EC GMP guidelines as well as DIN EN ISO 14644. It consists of an aluminium profile as a mounting frame for the ESG safety glass. This can be manufactured in any required dimension. The all-glass wall can be easily combined with all other clean-tek wall systems.

Features and advantages:

- Maximum design flexibility when combined with clean-tek wall systems

- Create a bright and pleasant working atmosphere

- No isolation of employees in closed rooms

- Promotes safety and order in production

- Resistant to chemicals

- Rare glass breakage due to the use of safety glass panels with integrated predetermined breaking points

- Each glass element can be replaced individually

- Compensation for uneven floors

- No carrier material for microbiological growth

- Easy to clean and resistant to disinfectants